sublimation screen ink

Sublimation inks are designed to apply a mirror image onto paper for transfer to the final substrate. The prints are transferred

via heat and pressure onto most polyester or synthetic materials. When first printed onto paper, sublimation inks appear to be

weaker and duller than standard inks, however when transferred onto suitable substrates, the dyes develop their true color

strength and brilliance.

Advantages

(1)Good stability on the machine,clear dot reproduction,excellent ink-water balance.

(2)Be able to adapt to the demand for middle-speed or high-speed printing.

(3)During the normal condition, use the ink on the machine directly.

Suitable Fabrics

Polyester fabric, Triacetate fabric, Nylon fabric, Acrylic fabric, Polypropylene nitrile.

Typical Uses of Zhongliqi Sublimation Offset Ink

Surfboards , Skateboards , Snowboards , Skies , Custom Furniture , Interior Design , 3D dye sublimation applications,

sublimation aluminum sheet , key rings , display products , plates , mugs , ceramic etc.

use method description:before using this ink,first Stir and then use.Depending on thin or thick,add water,A bunch of pulp,

or thickener.

Step 1.depending on the sophistication of required text or graphics,with 120-300 mesh screen printing,heat transfer ink per

kg could printable 10-17m2,on transfer machine at least 3-4 times.Using the screen printing method is particularly suitable

for large-scale yin Yang version, totally real end of the multi-color printing can really improve the effectiveness and reduce costs.

Step 2.paper requirements:silk screen with 80 grams,120 grams kraft paper (roll),you can transfer more than 3-10 times,not

coke,not bad and not to fight wrinkles,suitable for the real end printing the large of Yin version.

Step 3.Screen printing requirements:printing the required text or pattern,the specific use of the number of mesh screen should

be based on the number of transfer required and the transfer of fine text pattern,such as transfer three times with 200 mesh

printing,120 mesh printing can transfer more than 4 times.

Step 4.Reference number:such as color need to transfer red,the ratio:100% in magenta,and yellow for the 35% -40%,after the

transfer as a big red. Positive blue ratio:Green for 100%, Magenta 20%, after the transfer as positive blue. positive the proportion

of green: green 80%,yellow 90%,after the transfer as positive green.

Xinxiang Zhongliqi Printing Material Co., Ltd is the largest chinese manufacturer of sublimation inks for all commercial printing

applications, including offset lithography printing, digital printing, silk-screen printing and rotogravure printing.

We supply the industry with the best dye sublimation inks on the market. Such as offset sublimation inks, fluorescent sublimation

inks, digital sublimation inks, silk-screen sublimation inks and rotogravure sublimation inks.

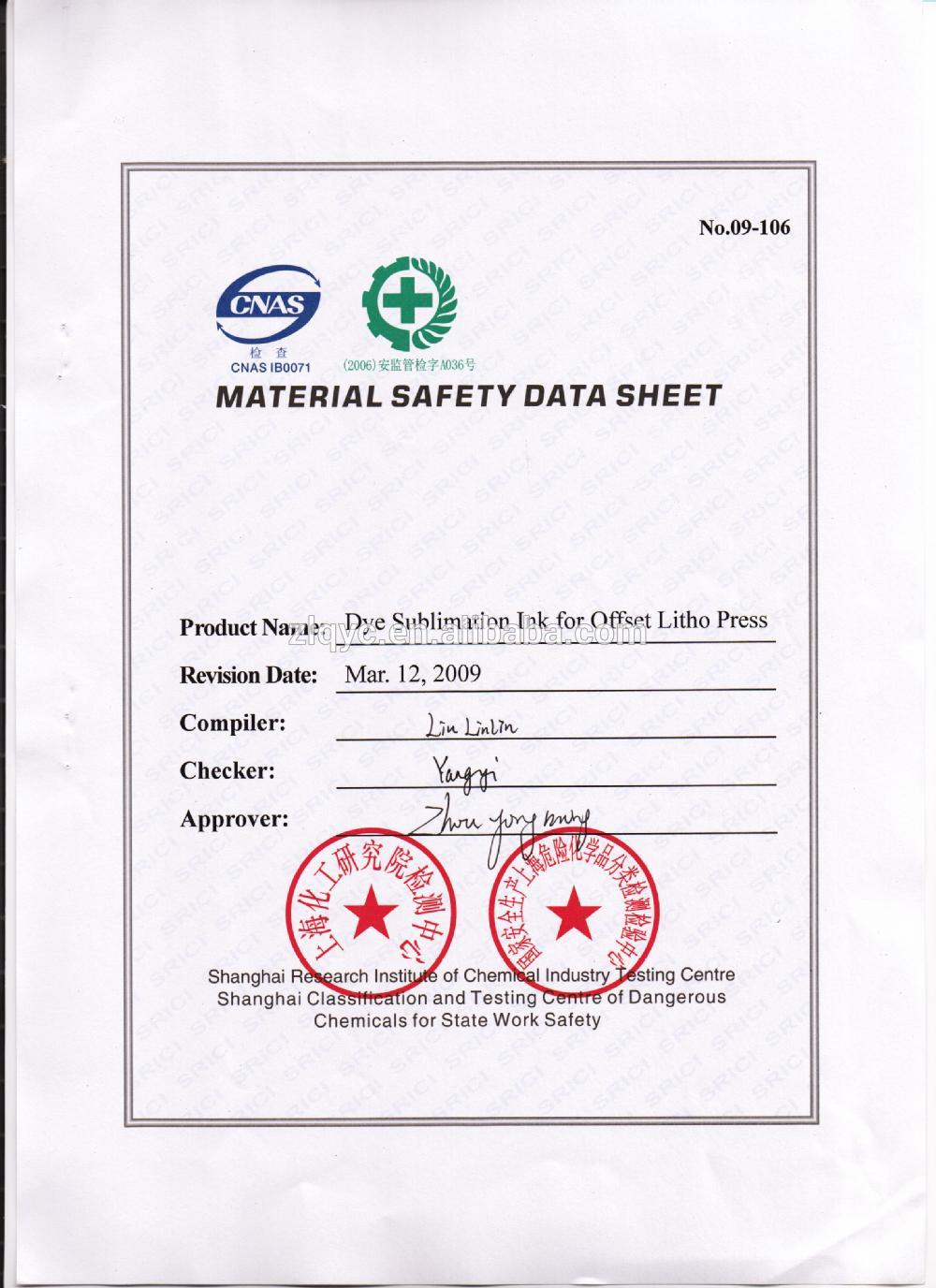

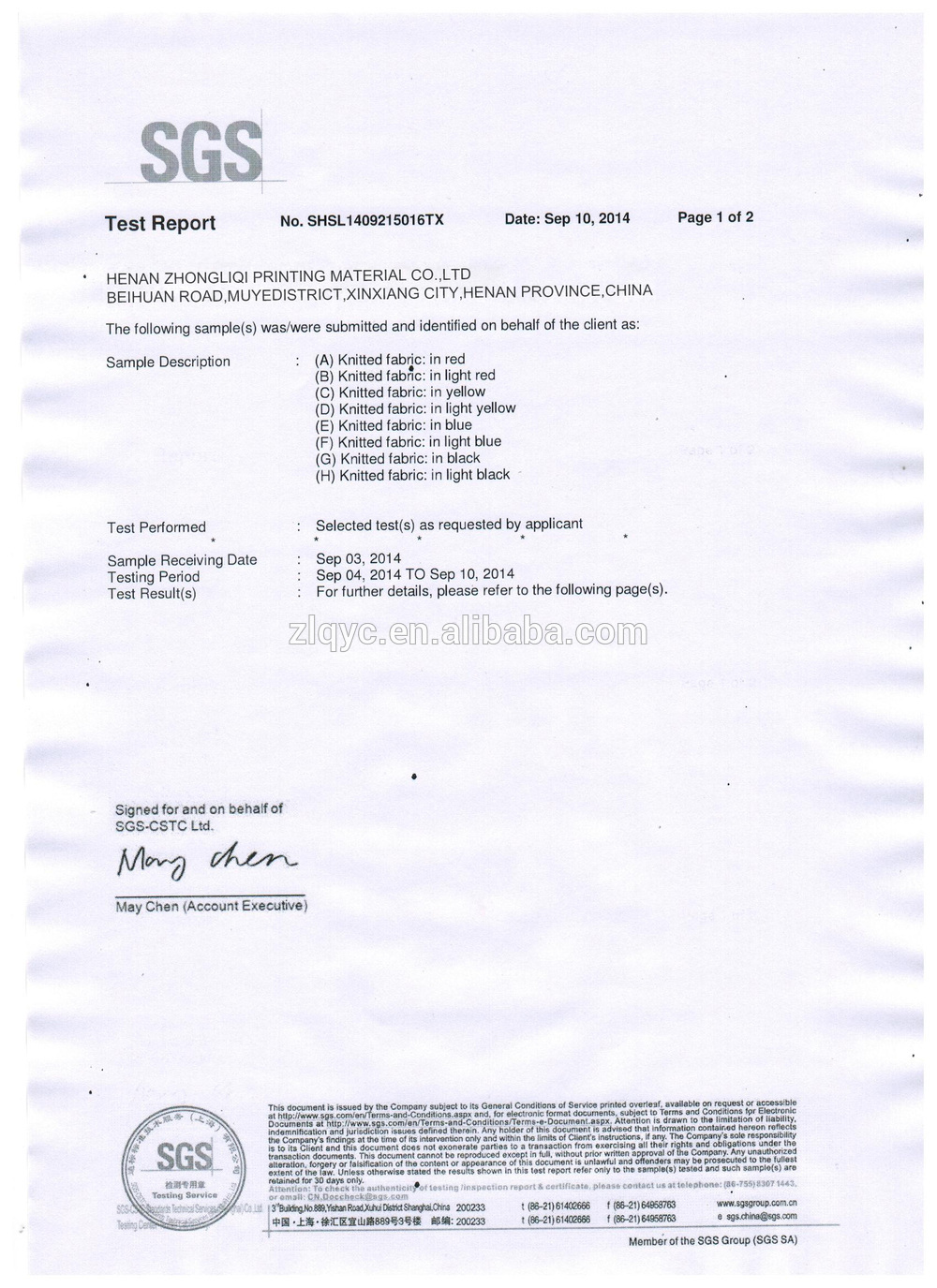

We are famous for superior quality, competitive prices, first class craftwork, safe packages and prompt delivery. Our sublimation

inks have passed the national MA in environmental testing, SGS , MSDS, DGM, etc. Therefore, we can fully satisfy your demands

and have a large customer base.

Our certificate

Address: Beihuan Road,Muye District,Xinxiang City,Henan Province,China

Mobile/whatsapp/viber: 008615517365582

Email: overseas03@zlqyc.com

Skype: angela.zlq

Fax: 86-373-2611121

Tel:86-373-2611121